Design

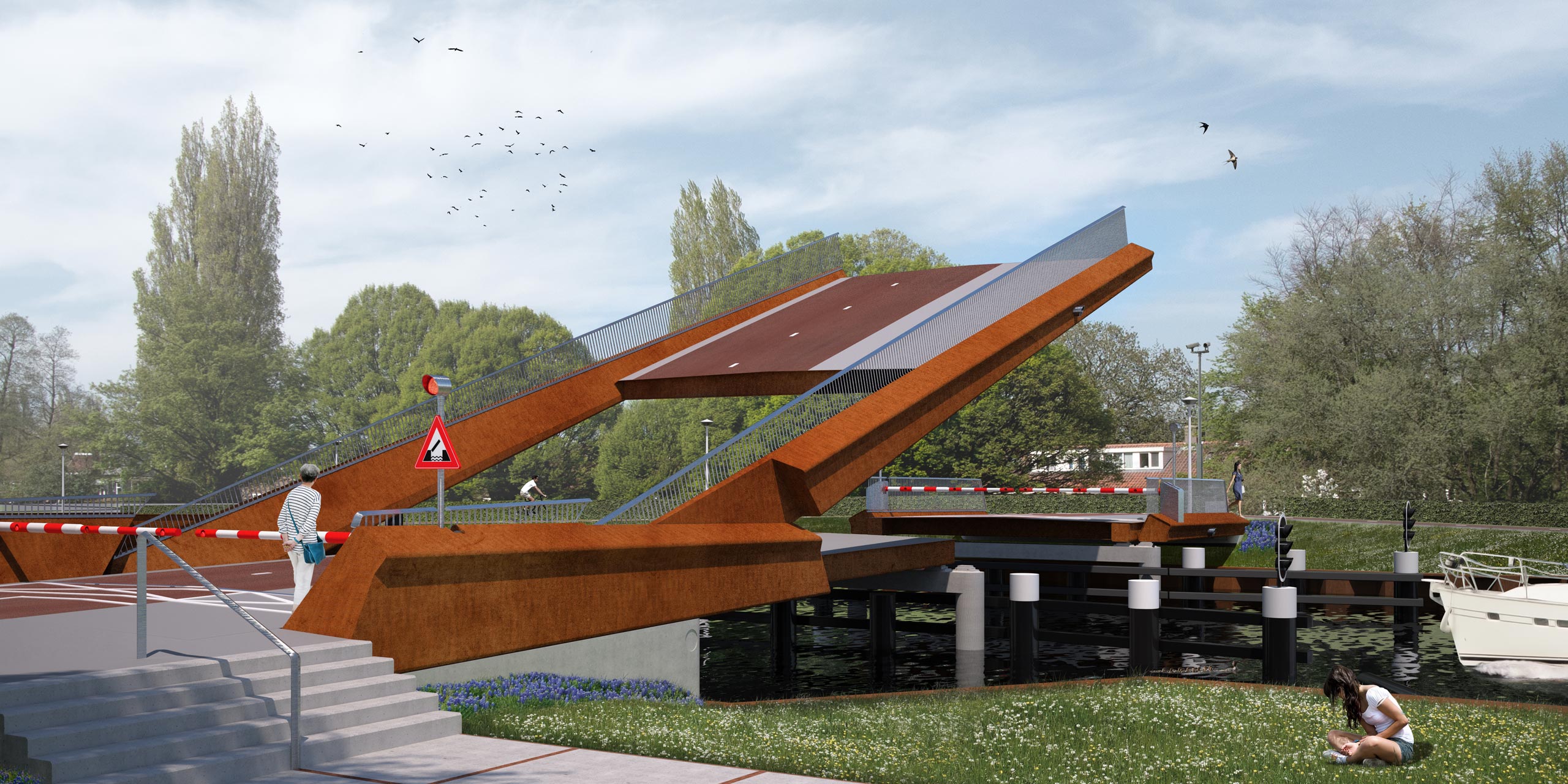

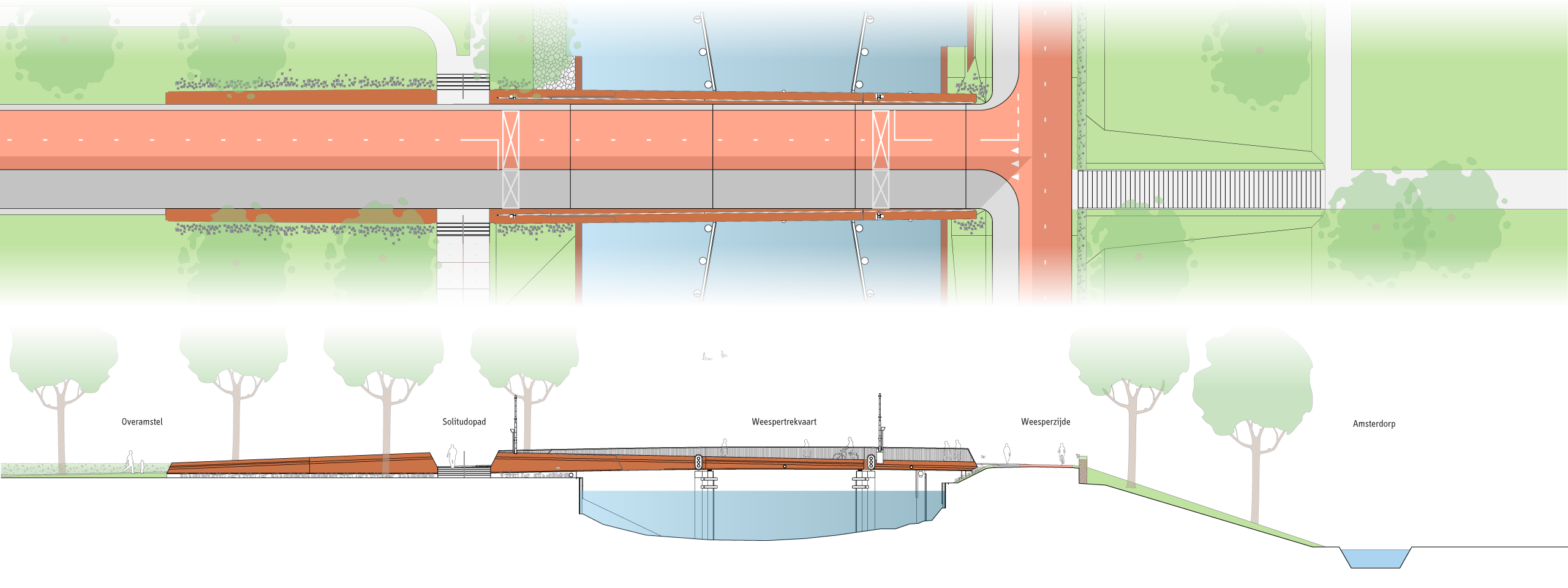

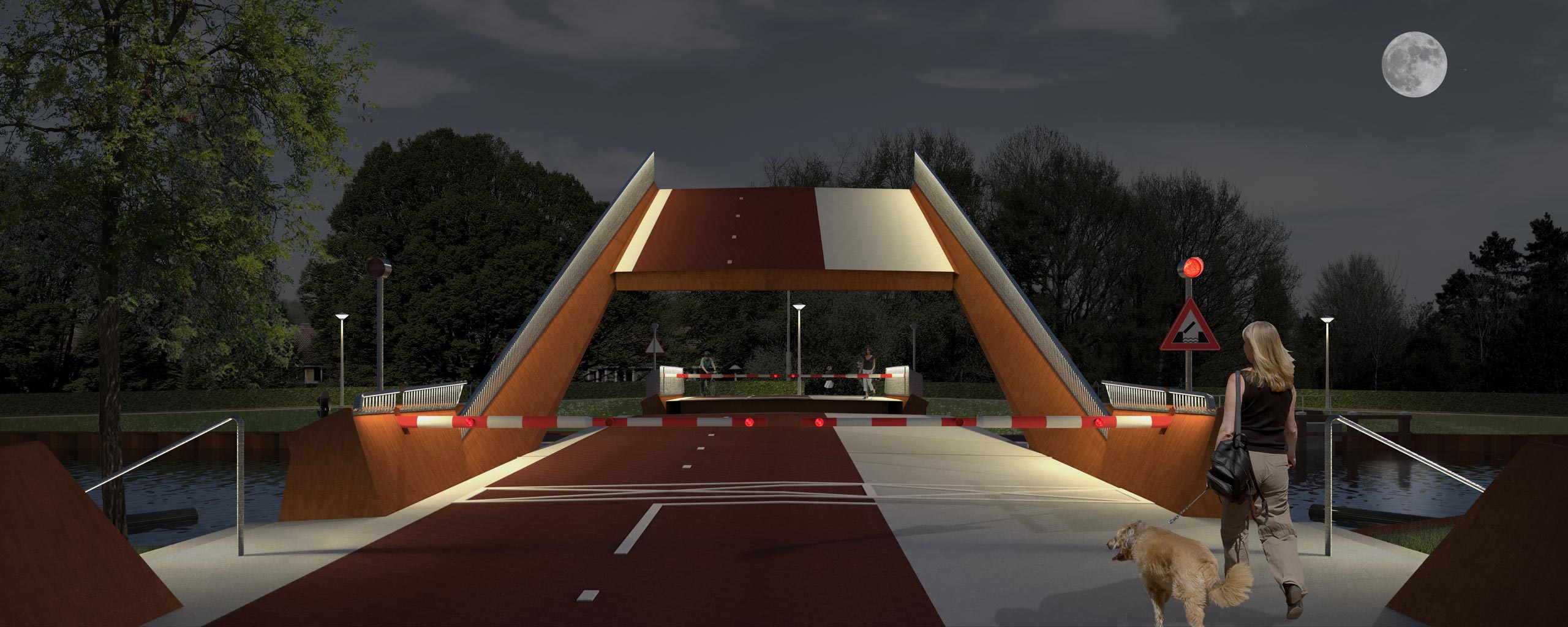

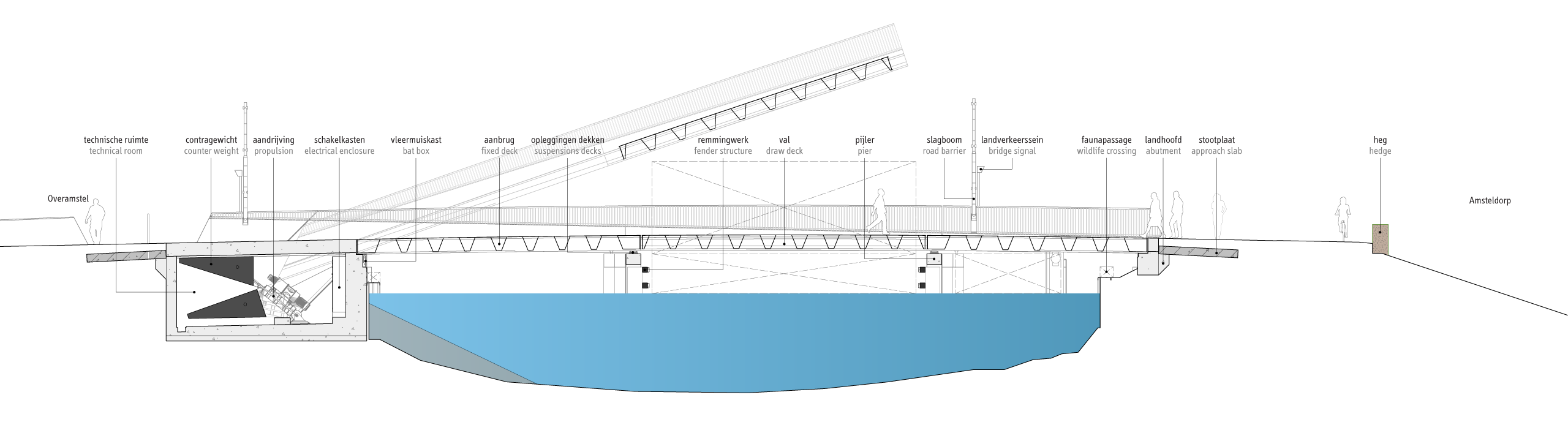

Approach spans merge with the arch into a single form. The visible structure is executed in weather-resistant steel, in line with the rugged environment. Virtually the entire surface consists of bent and flat steel plates, without visible welds. This greatly contributes to the perception of the entire bridge as a unified entity. The design ensures minimal disruption to the unobstructed view over the canal. In the water, only the slenderest possible pillars and mooring structures are present. The technical space is positioned on the shore; water damping is not necessary.

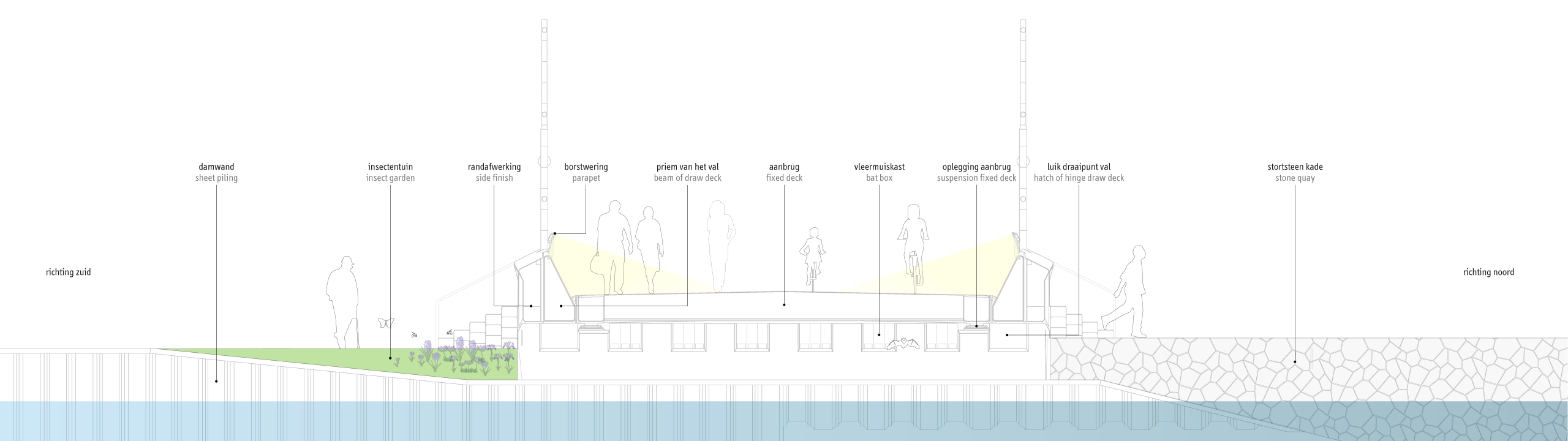

Bridge and landing form a unified entity thanks to the continuous parapet. The sturdy parapet aligns well with the theme of walled areas and buildings in the Overamstel area, not least that of the Bijlmerbajes itself. On the Weesperzijde, the dike is locally elevated. The bridge smoothly and comfortably connects to the bicycle and pedestrian path along the water. Boom barriers and road traffic signals together constitute a single “fixture.” Mooring structures, pillars, and maritime signals are kept modest in form and placed close to the water in a single color.

Flora and Fauna

We are creating wildlife passages on both banks. Additionally, new wildlife exit areas will be established on both sides of the canal. Swallow and bat boxes will be incorporated into the abutment beneath the bridge deck. These boxes are situated in the sheltered area deep below the deck where it is dark and dry. On the Overamstel side of the abutment, a garden with bee and butterfly-friendly flowering plants will be established. We have designed a planting schedule that ensures prolonged flowering throughout the entire flying season. The garden also provides a sloping access to the wildlife passages beneath the bridge.

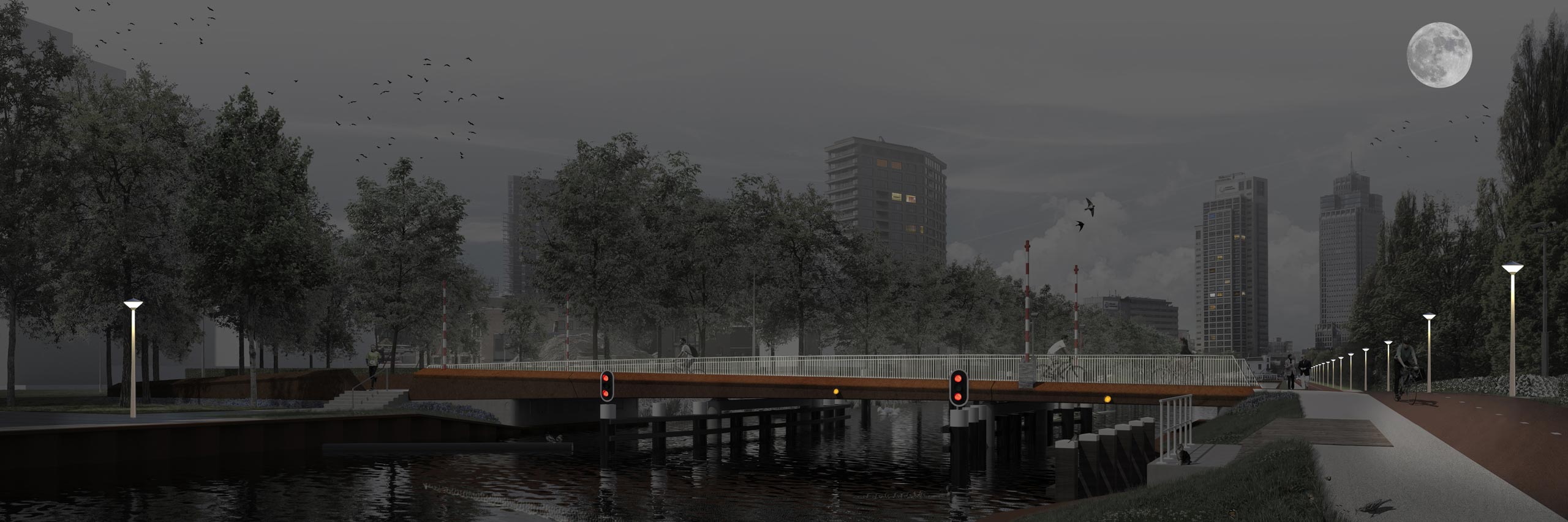

The slanted shape of the handrail ensures that the LED lighting radiates onto the deck. Together with the tall closed parapet, this prevents the light from radiating into the surroundings. Additionally, the lighting features a warm color temperature, ensuring that it doesn’t emit harmful blue light during the night. Nocturnal animals are not disturbed by these measures.

Technique

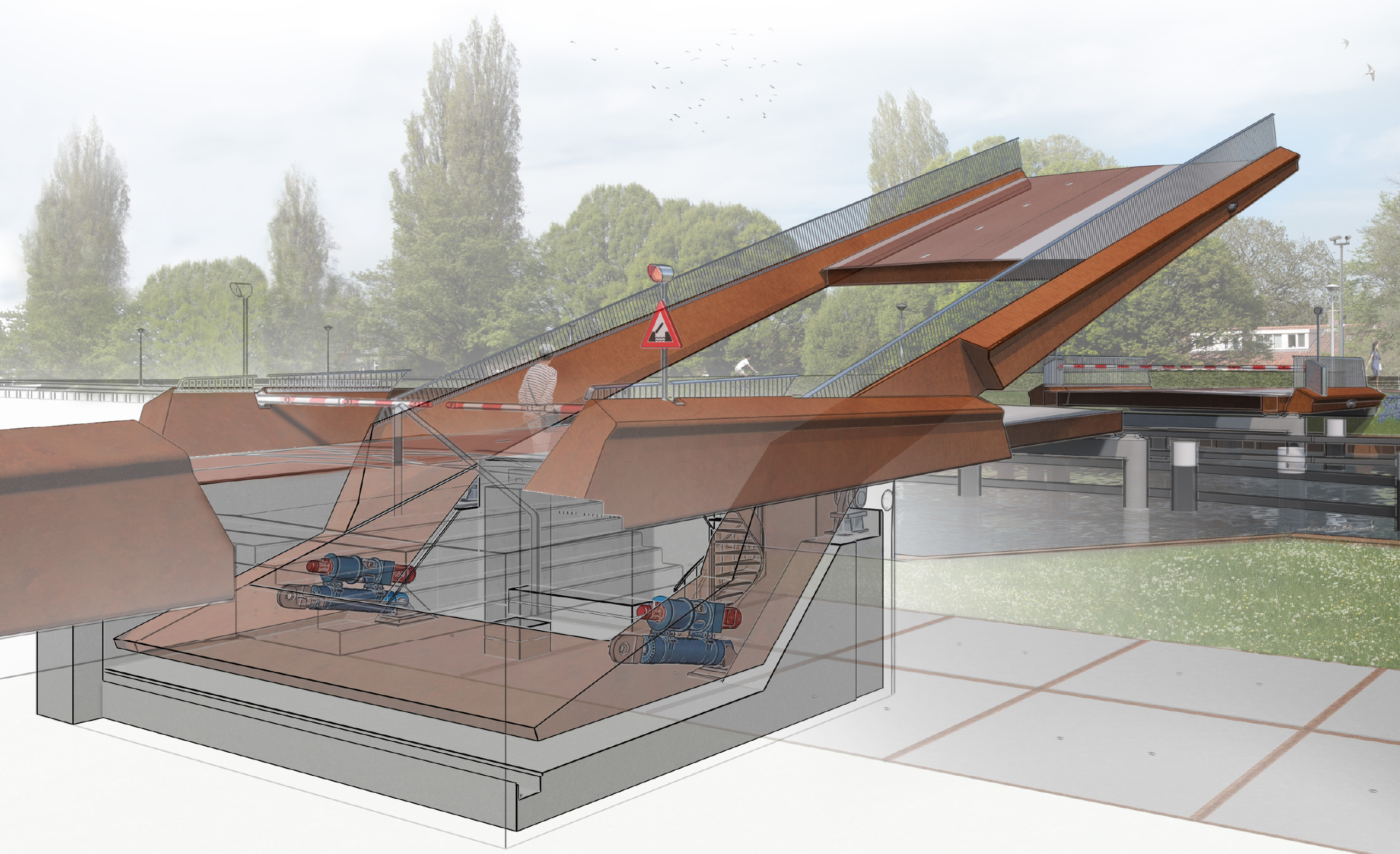

The clearance for navigable bridges is usually unrestricted. However, at this location, a clearance height of five meters is sufficient. By positioning the hinge closer to the shore, the clearance height is achieved with an opening angle of just 18 degrees. This allows the bridge to be operated efficiently. The bridge’s mechanics are well protected and secured: counterweights, motors, and control cabinets are placed together in an underground technical space. Vandals cannot access it, and it remains unaffected by weather conditions.

The weather-resistant steel structure is very lightweight (150 kg/m2), requires no preservation (and thus no toxic substances), and at the end of its lifespan is entirely recyclable while retaining its primary properties. The movable section and approach spans are manufactured in two parts, transported to the location over the road, and then welded together on-site within a large tent. This construction method aims to keep the structure as lightweight as possible. The final outcome maintains the same welding quality as in the factory. The bridge is equipped with a slight bearing pressure to prevent fluttering. The handrail is galvanically isolated from the weather-resistant steel main structure, thereby preventing rust formation on the handrail.